Autonomous Mobile Cobot Light

AMR meets Cobot!

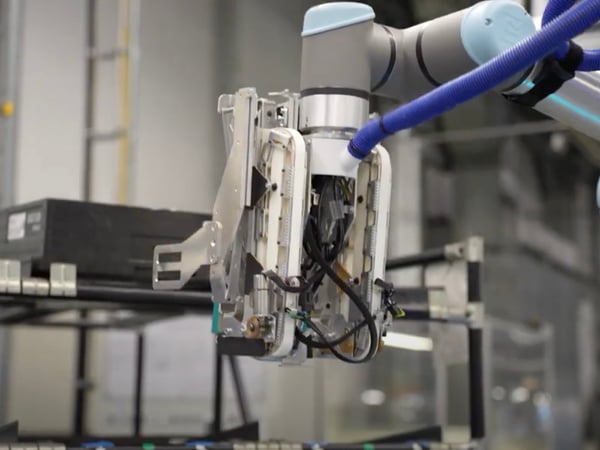

With the UR10 robot and the gripper, the AMC-L is specially designed for handling small load carriers. The strength of the AMC-L lies in the variability of the gripper system, which can be adapted to the specific requirements of your production process. Various grippers are available to choose from: The vacuum gripper, 2-finger gripper or the patented box gripper, which was developed by 4am Robotics. Integration into any master control system for order coordination not only optimizes the material flow, but also enables flexible and needs-based adaptation to different processes. With the help of a sophisticated system, even operation on demolition edges or stairwells is safeguarded.

By using the SLAM process (Simultaneous Localization and Mapping) in conjunction with safety laser scanners and 3D cameras, the AMC-L is able to navigate autonomously in complex environments. It constantly updates the map of its surroundings and simultaneously localizes itself in order to carry out precise movements.

A particular advantage of this AMR is that no additional markers or special markings are required for navigation. This enables flexible and efficient use of the AMC-L in different environments without the need for prior adjustments.

We also attach great importance to safety and comply with all current regulations and standards, such as DIN EN ISO 3691-4. This is important in order to minimize potentially dangerous situations and ensure a smooth workflow.

Trailer module for more throughput

To enable more material to be transported over longer distances, the AMC can be extended with an innovative trailer system with a towing capacity of up to 500kg (1,102.3 lbs).

The pivot point of the trailer coupling is aligned with the centre of the base. This means that the AMC can turn on the spot while the trailer simply remains stationary.

This ensures smooth and space-saving manoeuvring along the route.

Services Overview

-

Manipulation Weight: Max. 4 kg (8.8 lbs)

-

Vmax: 2,2 m/s (4.9 mph)

-

Boxes: KLT/Eurobox max. 800x600 mm (31.5x23.6 in) (WxL) max. 320 mm (12.6 in) height

-

Positioning precision: +/- 10mm (+/- 0.39 in)

-

WiFi, 4G/5G, VDA5050

You want more information on our products?

Please register with us, easily, via eMail address and you will get immediate access to our download area.

There you will find all product information at any time.